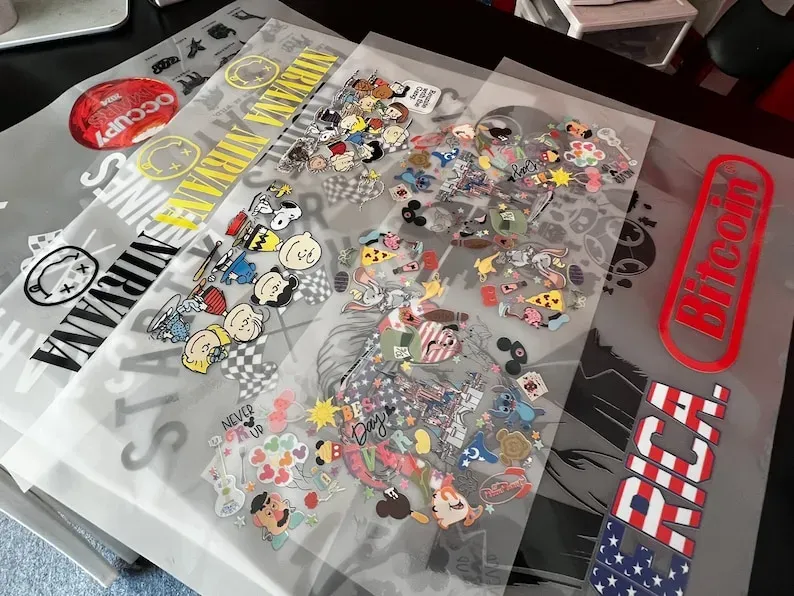

The DTF gangsheet is a game-changer in the world of Direct-to-Film printing, offering a remarkable solution for artists and businesses striving for efficiency and quality. This innovative approach enables users to print multiple designs on a single sheet, optimizing resources while achieving stellar DTF print quality. Emphasizing the importance of smart design practices, it’s essential to maximize the use of space and materials in your gangsheet builder projects. With the right techniques, you can expect not only cost-effective production but also vibrant, eye-catching prints that reflect your brand’s identity. In this article, we’ll explore effective strategies to harness the full potential of your DTF gangsheet, ensuring an efficient and impressive printing outcome.

The concept of a DTF gangsheet, or Direct-to-Film printing sheet, embodies a strategic method of layering multiple graphics on a single film to streamline the printing process. This method is rapidly gaining traction among designers due to its ability to enhance production efficiency and reduce waste. By utilizing advanced techniques and tools, users can create visually captivating printed designs that maintain high-quality standards. Additionally, the integration of a gangsheet builder facilitates the arrangement of artwork to maximize film usage without compromising on aesthetic appeal. As we delve further into this topic, you will discover essential design practices that can elevate your DTF projects to new heights.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology revolutionizes the way designs are transferred onto various fabric types. Unlike traditional screen printing, which can be costly and time-consuming, DTF offers a faster and more efficient way to produce vibrant prints. By utilizing a special transfer film coated with adhesive, DTF transfers a wide array of colors and designs directly onto fabrics, ensuring high-quality output that resonates with customers. The innovation in DTF printing also comes from its flexibility; it can be applied to cotton, polyester, and blends, making it a universal choice for custom apparel production.

Additionally, DTF printing excels in producing highly detailed images with sharp edges and vivid colors. This technology utilizes advanced ink formulations that stay vibrant even after multiple washes, enhancing the durability and longevity of printed garments. Because of its efficient printing process and versatility, DTF printing has become the preferred choice for small businesses and large-scale operations alike, allowing them to meet diverse consumer demands without sacrificing quality.

Best Practices for Using a DTF Gangsheet

Implementing best practices when creating a DTF gangsheet is crucial for maximizing print quality and minimizing waste. To begin with, it is essential to understand the layout of your designs on the gangsheet. Arranging multiple designs allows for efficient utilization of the transfer film, ensuring that the entire sheet is used effectively. This not only reduces material costs but also streamlines the printing process, allowing for quicker turnarounds on orders.

Additionally, ensuring that designs are aligned correctly on the gangsheet is vital. Utilize design software to preview how the final output will look on the film. This attention to detail will help you avoid any potential overlaps and ensure that each design shines on its own. Utilizing a DTF gangsheet properly involves planning and thinking ahead, which results in prints that don’t just meet customer expectations but exceed them.

Enhancing DTF Print Quality Through Design

The quality of DTF prints is heavily influenced by the design choices made prior to printing. One of the key elements to consider is the choice of colors. Using a vibrant RGB color palette can significantly enhance the final output. RGB allows for more vivid and eye-catching designs that attract attention, making your prints stand out in a competitive marketplace. Furthermore, the meticulous selection of colors aids in representing your brand’s identity and message effectively.

Moreover, the resolution of artwork plays a critical role in achieving high-quality prints. Utilizing high-resolution images ensures that print details remain crisp and clear, even when enlarged on a garment. To maintain optimal print quality, designers should always check the DPI settings of their files, using at least 300 DPI for best results. By prioritizing these design elements, you can ensure that the quality of your DTF prints consistently meets professional industry standards.

Tips for Efficient Printing with DTF Gangsheet

Efficiency in printing with DTF gangsheet starts with strategic planning. By reviewing your designs and considering their sizes, you can create a layout that maximizes the use of the gangsheet. Grouping smaller designs together not only saves space but also allows for easier handling during the printing process. This method reduces waste and makes the production workflow more streamlined and cost-effective.

Furthermore, take advantage of the capabilities of your DTF machine. Regular maintenance and calibration of the printer help in maintaining optimal performance, which impacts the quality and speed of your prints. Understanding your machine’s settings, such as temperature and speed, allows you to adjust based on the specific needs of your designs. This knowledge can lead to a significant reduction in misprints and material waste, ultimately enhancing your printing efficiency.

Common Mistakes to Avoid in DTF Printing

When diving into DTF printing, certain mistakes can derail your efforts and affect print quality. A common oversight is failing to manage the intricacies of layering and design overlap. When designs overlap on the gangsheet without proper attention, it can result in smudged or distorted prints. Regularly checking your designs before printing can save time and resources, ensuring that each piece turns out exactly as intended.

Another common pitfall to avoid is overlooking the importance of proper film handling. The quality of the film used plays a significant role in the success of DTF printing. Ensure that your PET films are properly stored and handled to maintain their quality. The wrong handling can lead to adhesion issues during the transfer process, which can compromise the final print quality. By being proactive in these areas, the consistency and quality of your DTF prints will greatly improve.

Final Thoughts on DTF Gangsheet Projects

In conclusion, mastering the art of creating effective DTF gangsheet designs is essential for anyone looking to thrive in the printing industry. By incorporating best practices that focus on design consistency, optimal color modes, and strategic utilization of space, you’re better equipped to produce high-quality prints that cater to your customers’ needs. Each element, from the selection of colors to the arrangement of designs, contributes to the final product and shapes your brand’s presence in the market.

As you embrace these design practices and strategies, remember that continuous improvement and learning will lead to greater efficiencies and enhanced print quality. The world of DTF printing is dynamic, and adapting to new features and developments will ensure that you remain competitive. Whether you are a seasoned professional or a newcomer, efficient DTF gangsheet management will pave the way for success in your printing projects.

Frequently Asked Questions

What is a DTF gangsheet and how does it work?

A DTF gangsheet refers to a sheet used in Direct-to-Film (DTF) printing that allows for multiple designs to be printed simultaneously on a single sheet. This method enhances efficiency in printing by maximizing the use of transfer film, reducing waste, and minimizing costs associated with printing individual designs.

How can I improve DTF print quality using my gangsheet builder?

To improve DTF print quality with your gangsheet builder, focus on using RGB color mode to achieve vibrant colors, ensure proper handling of films like PET, and use high-DPI images. Additionally, maintain design consistency and avoid overlaps between graphics to further enhance the quality of your prints.

What are the best design practices for creating a DTF gangsheet?

The best design practices for a DTF gangsheet include maintaining design consistency across all elements, using the RGB color mode for more vibrant prints, efficiently grouping designs to maximize film usage, and following a structured design process. Additionally, avoid common mistakes like improper graphic overlaps to ensure optimal results.

Why is RGB color mode preferred for DTF printing gang sheets?

RGB color mode is preferred for DTF printing gang sheets because it allows for a broader spectrum of colors, resulting in more vibrant and saturated prints. This color mode is particularly advantageous for achieving high-quality results that are visually appealing and accurately represented on digital screens prior to printing.

What tips can help maximize film usage in a DTF gangsheet layout?

To maximize film usage in a DTF gangsheet layout, group smaller designs together to fill in gaps effectively and consider variations in sizes to occupy the sheet without overcrowding. Strategically arranging your designs will enhance cost-efficiency by ensuring every inch of transfer film is utilized.

What are common mistakes to avoid when designing a DTF gangsheet?

Common mistakes to avoid when designing a DTF gangsheet include inadequate handling of film materials, neglecting to use high-resolution graphics, and allowing graphics to overlap improperly. By being aware of these pitfalls and implementing careful design planning, you can significantly improve the quality of your DTF prints.

| Key Points | Details |

|---|---|

| Keep Design Consistency | Implement consistent dimensions, color palettes, fonts, and spacing to enhance brand identity. |

| Use RGB Color Mode | RGB allows for vibrant prints and better accuracy on screens, standing out against CMYK. |

| Maximize Film Usage | Strategically place designs to minimize waste and cut costs. |

| Step-by-Step Design Process | Prepare assets, use vector graphics, and size artworks correctly for best results. |

| Avoid Common Mistakes | Handle materials correctly and check for overlaps to maintain quality. |

Summary

DTF gangsheet design practices are vital for creating high-quality prints that ensure efficiency and appeal. By focusing on consistency and employing the RGB color mode, designers can achieve captivating visual results while optimizing material usage. Understanding the step-by-step design process helps streamline production, reducing the chances of common mistakes. Overall, implementing these strategies not only elevates the quality of DTF gangsheet prints but also strengthens brand identity and production efficiency.